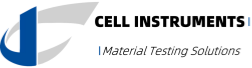

Core Compression Tester

Accurate and Efficient Bekk Smoothness Test for Paper and Board

About Us

Core Compression Tester

A Core Compression Tester is a specialized testing instrument designed to measure the compression strength of paper cores, tubes, and similar cylindrical packaging materials. These paper cores are widely used in industries such as paper, film, textiles, foils, and packaging, where their structural integrity is essential for efficient winding, handling, and storage.

Features

- Touchscreen operation system, automatic measurement, test result analysis and printing.

- Microcomputer processing system.

- Auto data collecting and printing.

- Embedded thermal micro printer.

- Real-time display of compression force, deformation and curve.

- Synchronous motor and accurate lead screw drive system.

Special equipment that meets standards.

Standards and Testing References

These standards define the proper testing methods for packaging performance, ensuring that results are globally accepted and comparable.

01

ISO 12048

Compression test for transport packages, widely used in packaging strength evaluation.

02

ISO 2872

Rigid containers, complete filled transport packages, vertical impact tests.

03

TAPPI 804

Compression test of fiberboard shipping containers.

Technical Reference

| Test Range | (25-10000)N |

| Testing Space | 301730 cm LWH |

| Resolution | 0.1N |

| Force accuracy | within ±1% |

| Indicating value variability | ≤±2% |

| Accuracy of deformation | ±1mm |

| Parallelism of Plates | ≤0.5mm |

| Standard test speed | 55 mm/min |

| Adjusting Speed | 140 mm/min |

| Unit interchange | N/Lbf/kgf |

| Printer | thermal printer |

Applications of Core Compression Tester

paper tube strength measurement

1. Manufacturing

- Paper Core & Tube Makers – Ensure strength for winding, stacking, and transport.

- Film, Textile & Foil Industries – Prevent core deformation during use.

- Packaging Converters – Guarantee stability and meet ISO 12048 / TAPPI T804.

2. Quality & R&D

- Inspection Agencies – Provide independent testing and certification.

- R&D Labs – Develop stronger, lighter, and eco-friendly core designs.

3. Logistics & Education

- Warehousing – Verify stacking strength for safe storage and shipping.

- Educational Institutions – Support research and training in packaging and materials.

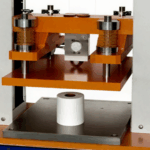

paper core compressive strength tester

Why Use a Paper Core Compression Tester?

Paper cores serve as the backbone for materials wound in rolls. Weak cores can collapse under stacking or handling, leading to costly product damage and operational issues.

- Accurate Strength Evaluation – Ensures cores withstand vertical loads during storage and transportation.

- Compliance with Standards – Testing according to ISO 12048 (Compression test for transport packages) and TAPPI T804 guarantees global reliability.

- Cost Reduction – Prevents failures in production lines and minimizes product wastage.

- Quality Control – Validates supplier quality and helps manufacturers maintain consistent performance.

Digital Paper Tube & Paper Cone Compression Tester

Choose Cell Instruments Core Compression Tester

Cell Instruments is a professional manufacturer of material testing equipment, specializing in packaging, paper, film, medical devices, and food contact materials.

- High Accuracy & Repeatability – Reliable results with advanced load cell technology.

- Customizable Fixtures – Compatible with different sizes of paper cores and tubes.

- User-Friendly Interface – Easy operation with digital display and automated data collection.

- Compliance Ready – Fully meets ISO 12048, ISO 2872, and TAPPI T804 standards.

- Global Service & Support – Trusted worldwide with professional after-sales support.

With our expertise, manufacturers can ensure that every roll of material is supported by a robust, tested paper core.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985